Microwave drying of insects

Our customer needed a quick and efficient solution to gently and homogeneously dry mealworms, mainly intended for the pet food industry. Discover how our microwave drying equipment fully meet their needs.

SAIREM’s microwave and radio frequency drying solutions provide fast, gentle, and energy-efficient drying for food products like herbs, spices, insects, fruits, and cheese. Unlike conventional methods, our technology ensures uniform moisture removal while preserving flavors, nutrients, and textures.

By drying from the inside out, SAIREM’s solutions prevent overheating, reduce processing time, and maintain high product quality for premium food applications.

We ensure rapid drying in just a few minutes with direct product heating.

Our experts can answer your additional requests by offering custom-made solutions. Feel free to contact us.

Dried herbs are used in the food, pharmaceutical and medical industries.

Fast Microwave drying: 2-3 times faster than hot-air drying in the worst conditions, and 10-15 times faster in typical conditions.

Better preservation of appearance and properties: Microwave drying better preserves the appearance and color of herbs by rapidly inactivating enzymes. It also preserves active ingredients, nutrients and flavors.

Reduced energy consumption: Microwave drying consumes less energy than hot-air drying.

No C.Perfingens and <10 cfu/g of entereobacteria.

To meet the growing demand for insect proteins, microwave drying offers an effective solution. It is particularly well suited to insects used in animal and human nutrition, such as black soldier fly larvae and, above all, mealworms.

The advantages are like those of other applications:

Homogeneity: Final drying product is homogenous.

Fast & repeatable Process: Microwave drying quickly removes moisture, reducing drying time to minutes. This speed and precise control ensure consistent, repeatable results.

Preservation of taste and appearance: Microwave drying preserves the natural shape of product.

No C.Perfingens and <10 cfu/g of entereobacteria.

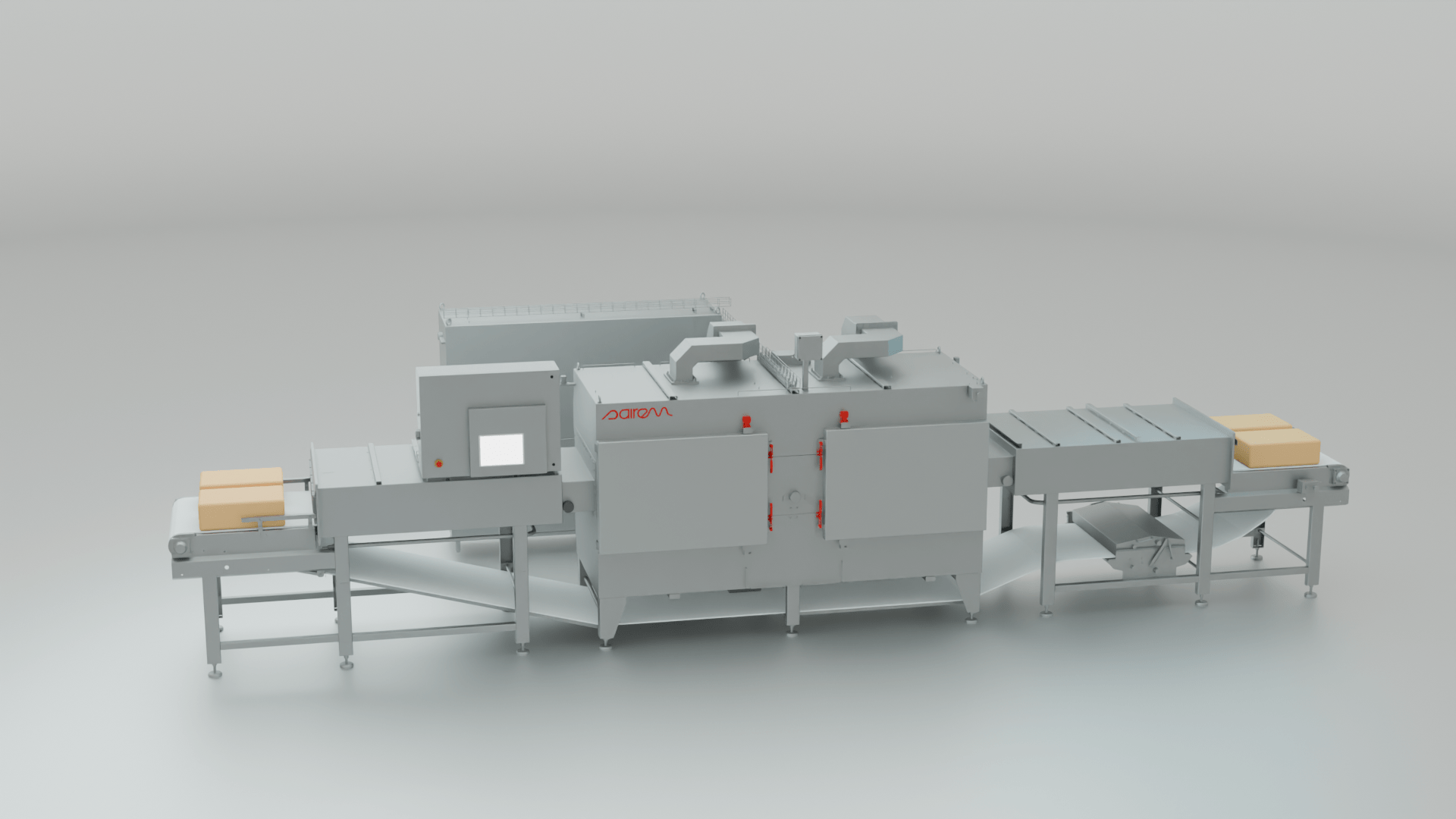

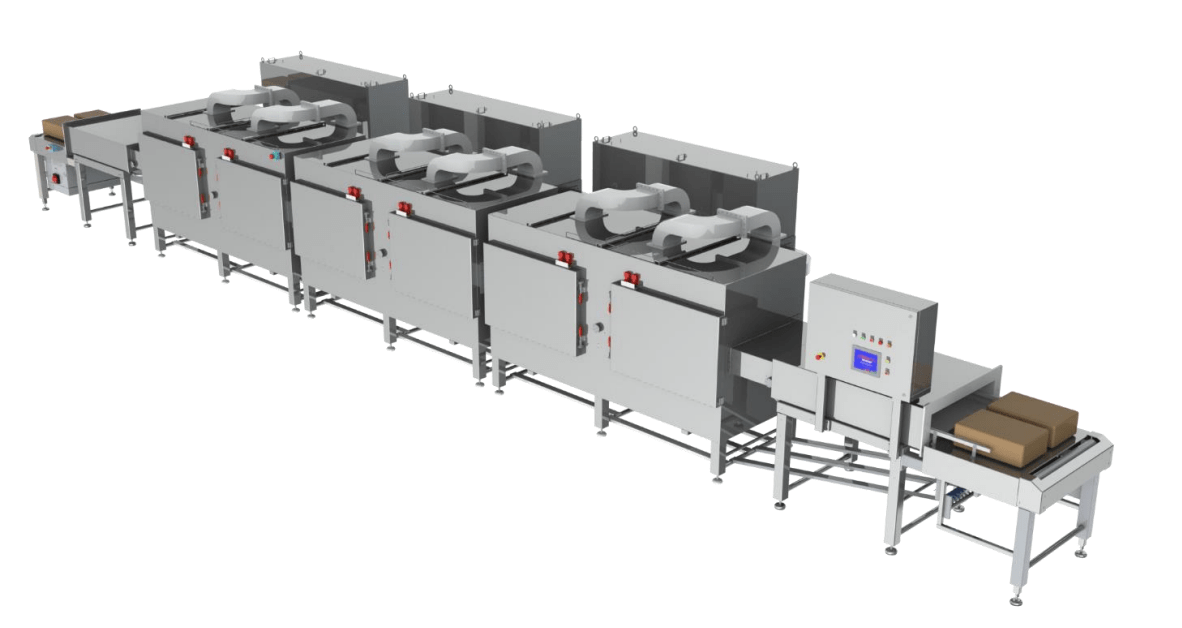

Microwave drying tunnel with power of 75 kW

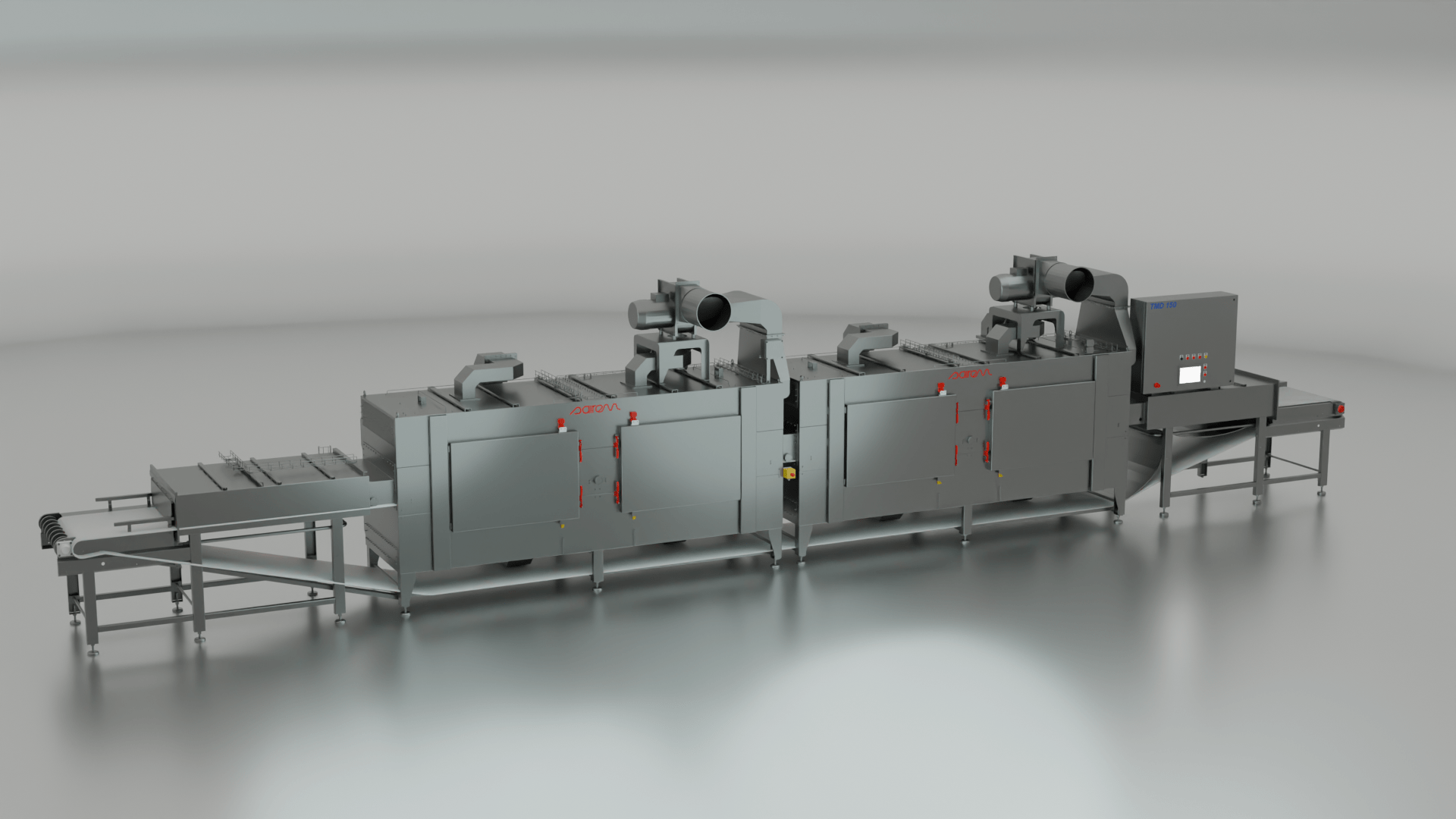

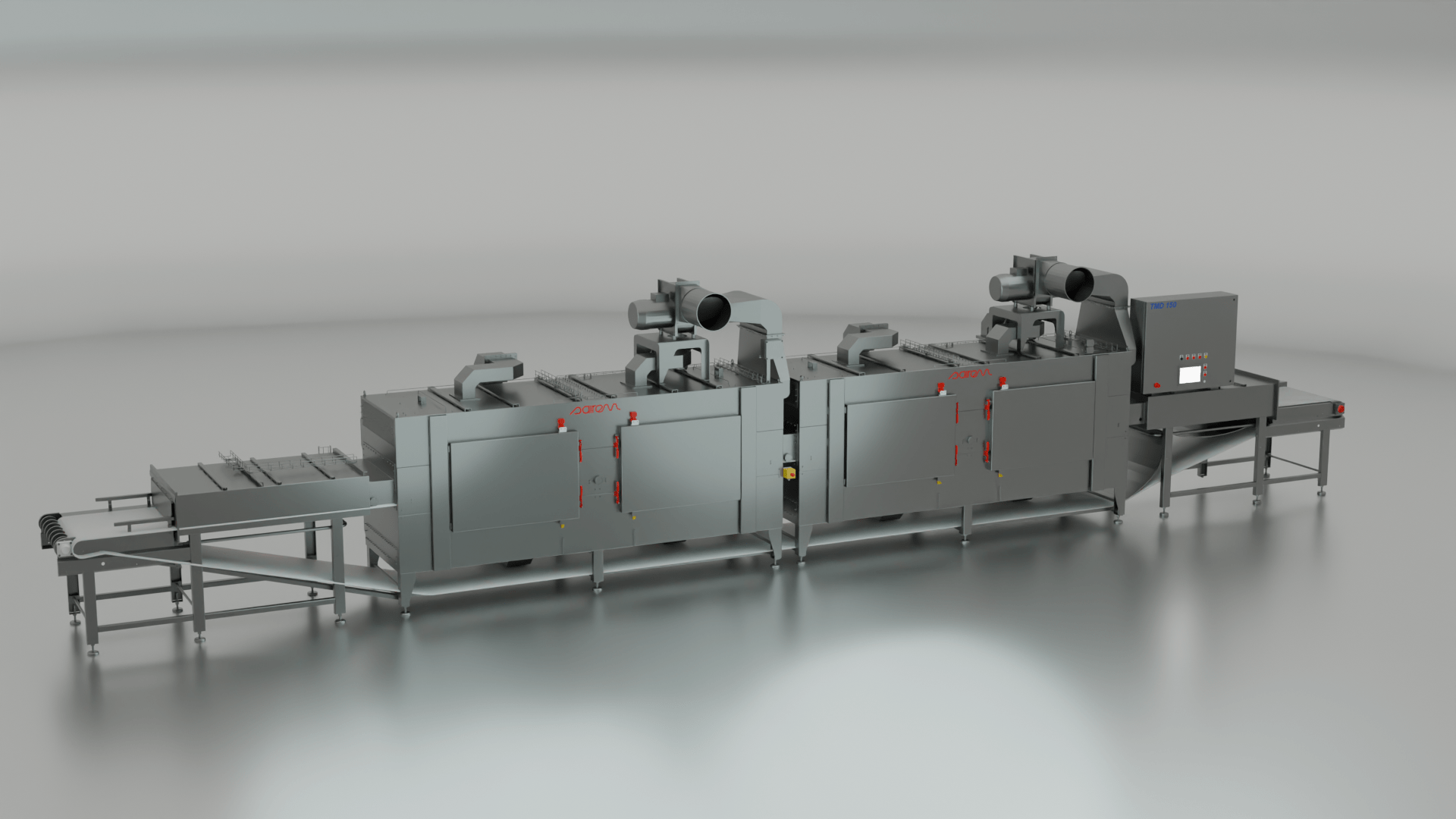

Microwave drying tunnel with power of 150 kW

Microwave drying tunnel with power of 225 kW