What are the different liquid heating processes ?

When it comes to fast heating of liquids and viscous products, there is different technologies available. Discover which are the most common ones and what are their characteristics.

Most processes are based on a principle of heat exchange, which function by transferring thermal energy from one liquid, commonly water, to another. The primary source of heat energy is predominantly derived from either steam or hot water generated by a gas boiler or an electric power supply.

Main principle of liquid heating

Depending of the product you want to heat, either for food processing or industrial purpose, most of the liquids are heated thanks to heat exchange technology. Basically, the thermal energy is transferred from a heat transfer fluid, usually hot water or steam, to the liquid product through an exchange surface who separate the fluids and avoid any change in their physicochemical properties.

The thermal energy exchange always occurs by convection: the larger the exchange surface, the more efficient the heat exchange, except for the microwave heating which directly heat the product. Discover the most common heat transfer methods below.

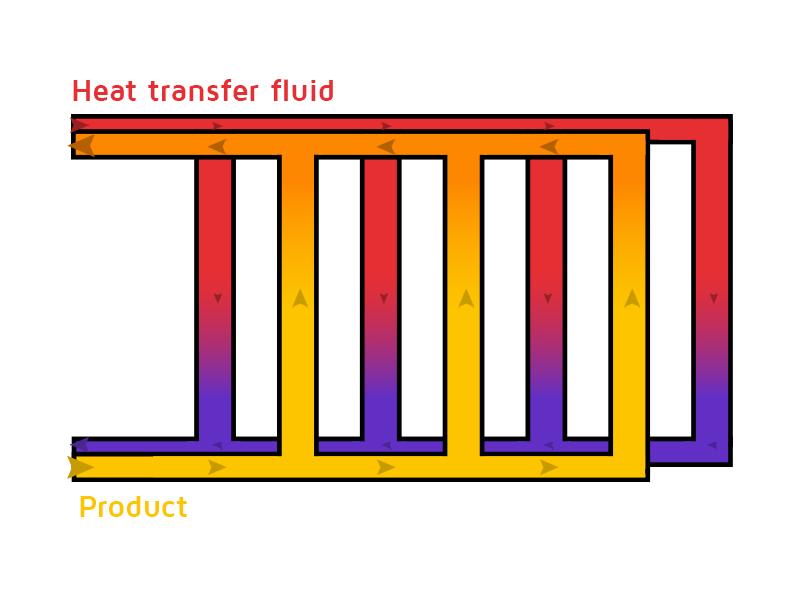

Plate exchanger

A plate exchanger is constituted of independent stainless steel plates in which circulate the heated liquid and the heat transfer fluid such as hot water. The plates are assembled and compressed against each other in a support called a frame. It is a handy equipment as you can easily clean it by removing all the plates. The footprint is small compared to the treatment flow.

However, it is an equipment that can not process liquid with pieces. In addition, its clogging gets dirty very quickly with too viscous liquids. It is therefore especially suitable for non-viscous and homogeneous liquids.

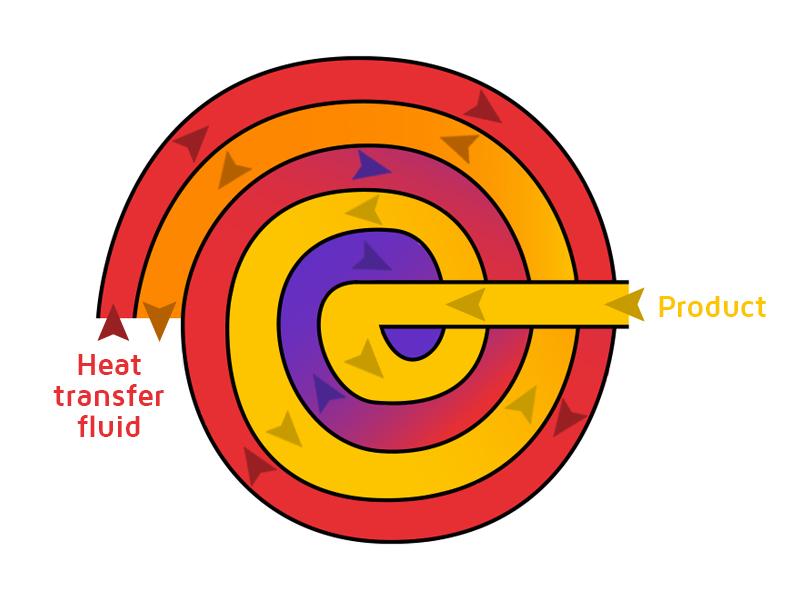

Spiral exchanger

A spiral exchanger is made of two stainless steel channels wounded together in which the heated liquid and the heat transfer fluid circulate at counter-current. The footprint is usually small for this type of heating equipment.

This equipment makes the heating treatment of a slightly viscous liquid possible. But the heat transfer coefficient is low which limits its use for important and fast temperature increases.

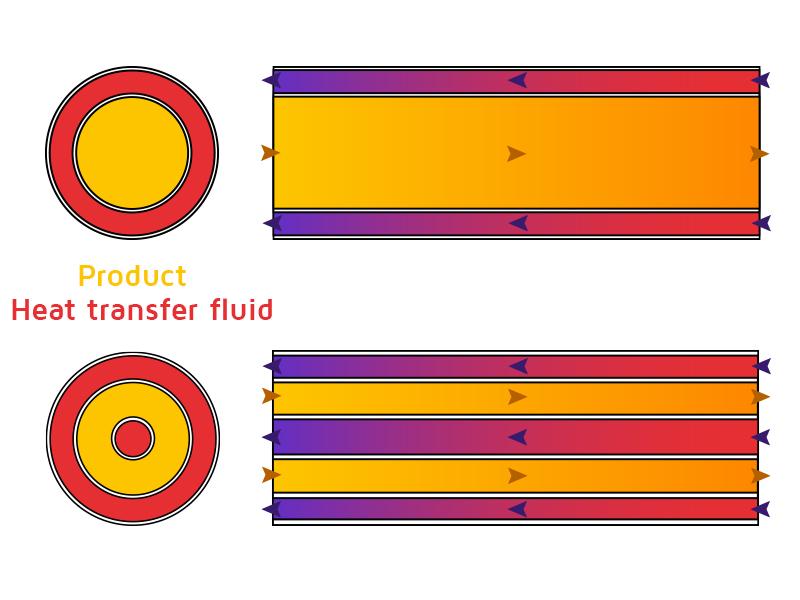

Tubular exchanger

Tubular exchanger have different operating configurations : single or multi-tubes. The principle is to have one or more tubes placed in a larger one where the heat transfer fluid circulates. The heat transfer is carried out by conduction from the outside to the center of the product. On an annular exchanger, the heat transfer fluid circulates in two pipes, one central and the other outside. The liquid product is transported between the two which allows it to be heated more efficiently.

This liquid heating system presents some advantages such as linear temperature rise and good temperature control. But the footprint is important and it’s not adapted to very viscous liquid.

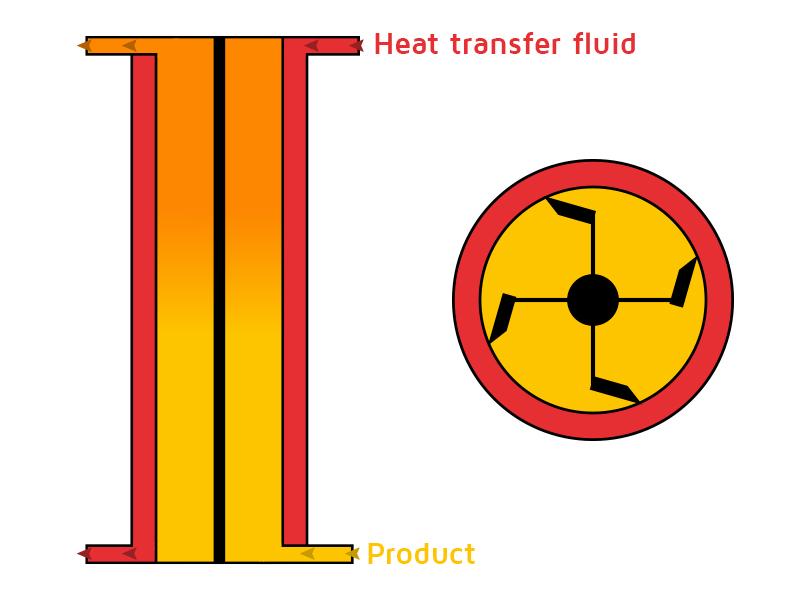

Scraped surface exchanger

A scraped surface exchanger is made of 2 elements. On the external part the heat transfer fluid transmit its thermal energy to the product. On the inside, the tube where the liquid product goes through is equipped with rotative blades that continuously scrape the internal transfer surface. The blades prevent the liquide product from settling and burning, and it increase turbulence for optimized heat exchange.

The scraped surface exchanger is one of the only system adapted to viscous and pasty products. But it has a high cost of investment and operation.

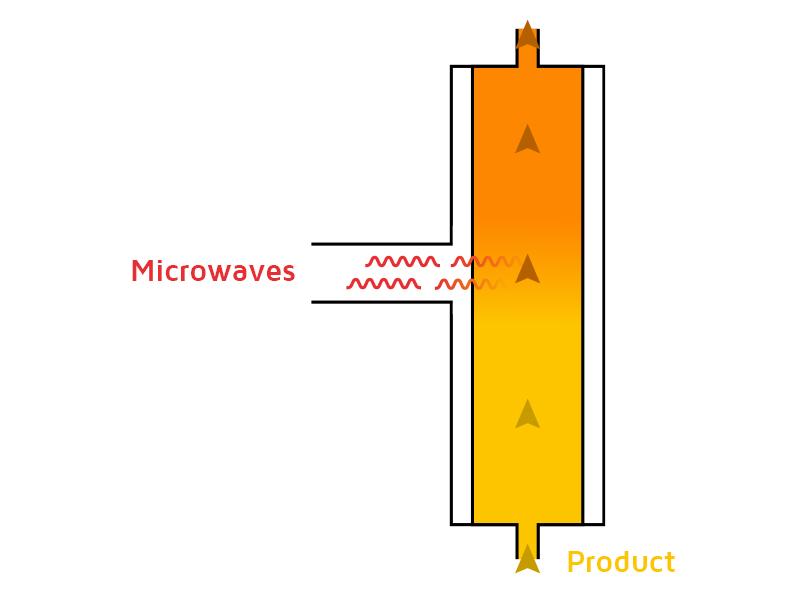

Inline heater by microwave

Unlike previous solutions where heat is transferred by conduction from the outside to the product through its surface, microwaves heat the entire liquid product mass directly and homogeneously, without the use of a heat transfer fluid. The heat generation is almost instantaneous and allows for a perfectly controlled thermal process.

Inline microwave heating is adapted for liquid or pasty products, with or without pieces (for example, jam). The direct thermal transfer from microwave energy to the product allow an excellent energy efficiency.

In conclusion, there are various industrial processes for heating liquids. However, not all are equivalent. Some heating methods have advantages for certain types of liquid products, while others allow for space-saving or heating products containing pieces, for example. Microwave heating of liquids, on the other hand, proves to be highly effective and efficient for all types of liquids while occupying limited space.

Seeking enhancement for your industrial heating process? Our skilled professionals are ready to assist you in discovering the optimal heating solution!

Contact us

Need help to find the best solution ?

Our free microwave and radio-frequency guide for food applications will help you to better understand these technologies, and find the solution the most adapted to your needs.

Download your guide