NaowaratSAENYAKORN

+33 (0) 6 35 47 42 72When performing PEALD, PECVD or PVD process, uniform plasma processes over large dimensions are essential for surface treatments at industrial scale.

Usually, uniform plasmas are processed over large dimensions, and most often require strong ionic assistance. They are essential for industrial scale surface treatments which require ever higher etching or deposition rates, such as plasma enhanced chemical vapor deposition (PECVD) or deep etching. These requirements have stimulated the development of uniform plasma sources, of high density, which, moreover, are capable of delivering high concentrations of reactive species.

Microwave plasma sources are well known for their performance in terms of creating high densities of reactive species. But they have often been considered second best given the difficulty of implementing them in an industrial process as most of them require an impedance adaptation system that is difficult to automatize.

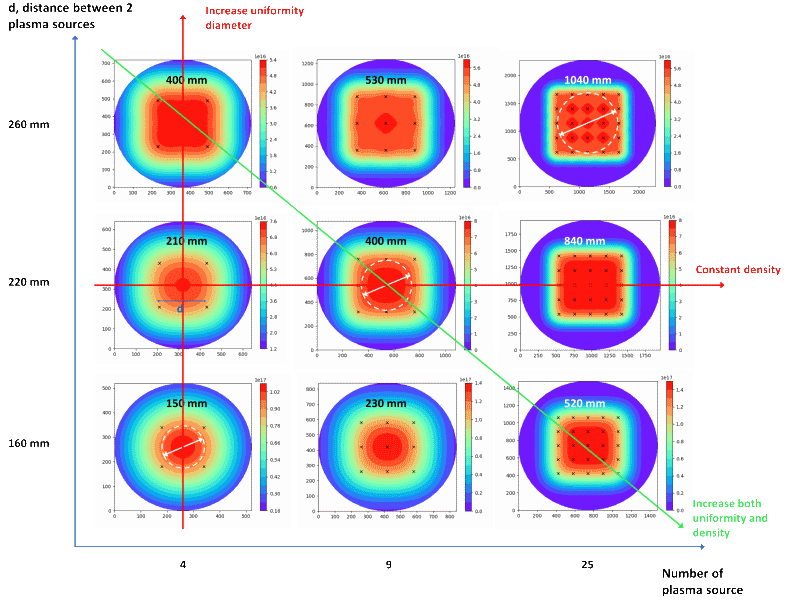

In addition, to create a large volume of plasma by overcoming the critical density limiting the propagation of waves, it is necessary to wisely distribute the plasma sources.

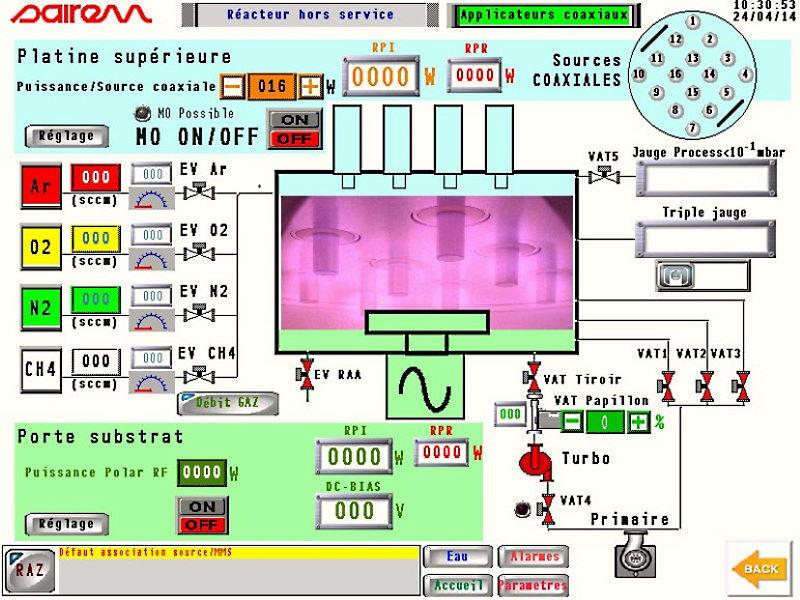

To overcome these constraints, we have developed two innovative self-matching plasma sources working with 2,45 GHz solid-state generators: Aura-Wave and Hi-Wave. The small footprint of our solution allows to create an array of plasma sources, without scale limitation.

On traditional RF or MW plasma sources, there is a lack of uniformity especially on the edges. By controlling the power of each source independently, our solid-state generators technology remove all these limitations, for any size of substrate.

With Aura-wave and Hi-wave plasma sources in matrix configuration, you can set-up infinite combination possibility :

This allows to develop processes with high plasma density and excellent uniformity over large scale.

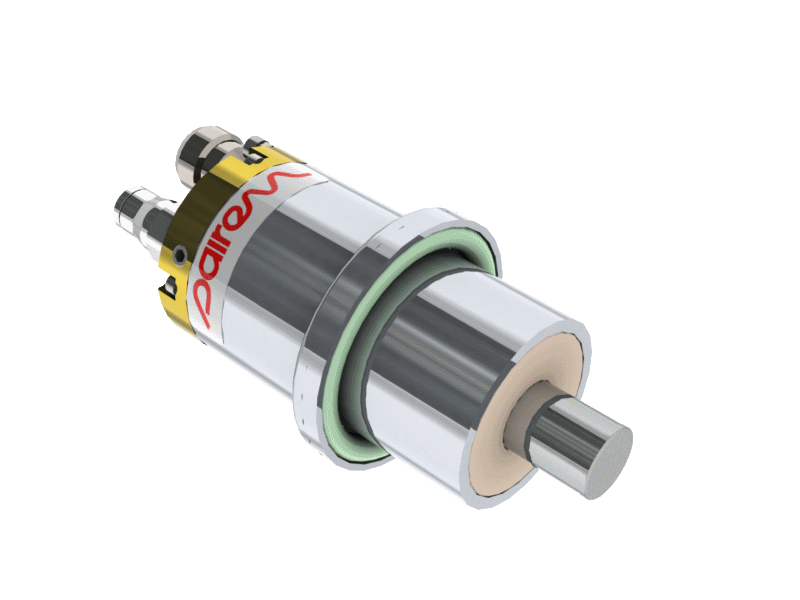

Aura-Wave is an Electron Cyclotron Resonance coaxial plasma source. It has been designed to be self adapted once the plasma is ignited. A magnetic field combined with the electromagnetic wave allows the creation of plasma at low pressure due to Electron Cyclotron Resonance. The Aura-Wave source has been designed to sustain microwave plasma over several decades of pressure and from a few watts, whatever the gas.

The source makes it possible to reach plasma densities of 10 11 cm -3 in multisource configuration at 10 cm from the source plane with most gases.

Find our latest reaserch on our Aura-Wave ECR microwave plasma sources here !

More information about Aura-Wave

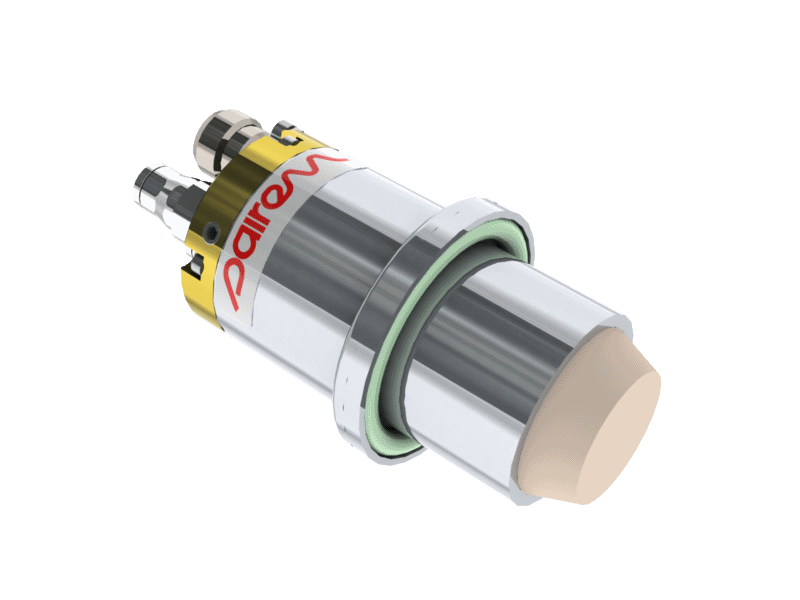

The Hi-Wave collisional coaxial plasma source was designed to avoid internal power-losses and has proved to be matched, i.e. no reflected power, with no additional impedance matching system over 1 pressure decade, depending on the plasma gas.

Hi-Wave is a collisional type microwave plasma source is thus intended to operate without magnets in the collisional regime.

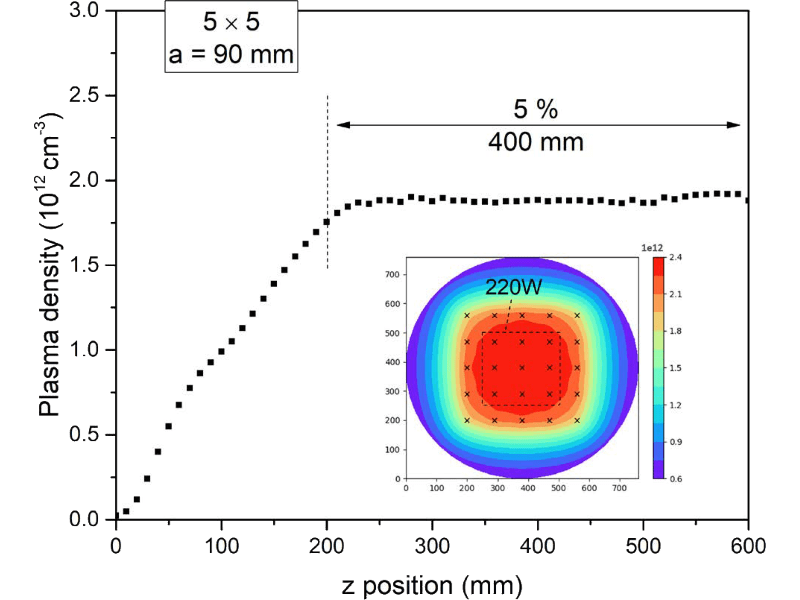

Plasma densities greater than 10 12 cm -3 can be achieved in multi-source configuration at 10 cm from the source plane with most gases.

More information about Hi-Wave

Compact, reliable, and industrially designed, our OEM microwave plasma solutions are easily integrable into your own equipments. Our experts will support you on every phase of the process, by performing extensive simulations, to optimize your process.

We have years of experience in microwave and plasma system development. By choosing SAIREM, you are relying on a partner with a strong R&D, support culture, and high flexibility, since its origins.

Contact us

ECR plasma source

Collisional plasma source

Surface wave plasma source